As the New Year approaches, restaurant and grocery stores face one of the busiest times of the year. From preparing for surges in customer demand to managing supply chain complexities, ensuring that your shelves and kitchens are fully stocked—and not overstocked—can be a balancing act. At CJR Wholesale & DairyCentral, we understand the challenges and demands of peak seasons, and we’re here to help you optimize your inventory to make the most of this crucial time.

Here’s our guide to effective inventory management strategies that ensure you’re well-prepared for holiday demand while laying the groundwork for success in peak seasons year-round.

Forecast Demand with a Data-Driven Approach

Peak season planning starts with accurate demand forecasting. Use historical sales data from previous years to understand patterns and trends in holiday spending. This data can help you predict which products are likely to move quickly and where you might need additional stock.

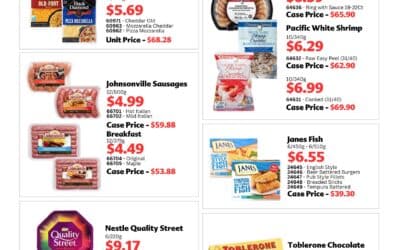

For restaurants, this may mean looking at reservation numbers or special event bookings to gauge demand. For grocery stores, analyze which items were in high demand during last year’s holiday season and consider any emerging trends, such as plant-based or gluten-free options, that may impact purchasing this year.

Prioritize Shelf-Stable and High-Demand Essentials

During peak seasons, items with longer shelf lives and consistent customer demand become essential. Focus on inventory that has a longer shelf life but is also holiday-specific, like baking supplies, canned goods, dry pasta, sauces, and specialty oils.

For restaurants, non-perishable ingredients allow you to keep staples on hand for extended periods, giving you flexibility in adjusting menus without frequent reordering. Meanwhile, grocery stores benefit by having ample supplies of items like spices, holiday baking ingredients, and specialty condiments that are popular during holiday cooking and gift-giving.

Pro Tip: Consider creating a “holiday essentials” checklist to ensure you’re well-stocked on the staples your customers will need.

Build Strong Supplier Relationships for Flexibility

One of the biggest challenges in peak season inventory management is maintaining a flexible supply chain. Strong relationships with suppliers can help you secure priority access to high-demand items and open up options for emergency orders or adjustments as demand fluctuates.

At CJR Wholesale & DairyCentral, we pride ourselves on building collaborative relationships with our clients, ensuring open lines of communication to manage last-minute needs or unexpected surges. A good supplier relationship can mean the difference between meeting customer demand and facing out-of-stock items when it matters most.

Benefits of Flexible Supplier Partnerships:

- Access to real-time updates on stock availability and lead times

- Potential for customized solutions and preferential treatment on urgent orders

- Greater reliability in unpredictable market conditions

Implement Inventory Tracking and Management Systems

Having a robust inventory management system in place allows you to monitor stock levels, set reorder points, and receive alerts when items are low. Automated inventory systems make it easy to analyze your current stock, track turnover rates, and see which items might need a reorder.

During the holiday season, real-time tracking is essential to avoid stockouts on popular items. Additionally, tracking systems can help you avoid overstocking by identifying slower-moving products so you can make adjustments early in the season.

For Restaurants and Grocers: Using inventory tracking to monitor your most popular holiday ingredients—whether it’s baking supplies or premium cuts of meat—can ensure you’re well-prepared for peak demand without carrying unnecessary surplus.

Prepare for Last-Minute and Seasonal Adjustments

Even the best-laid plans sometimes need adjusting. The holiday season often brings unexpected spikes in customer demand, last-minute menu changes, or delays in supply chains. Maintaining a degree of flexibility is key to navigating these fluctuations.

Strategies for Adapting Quickly:

- Seasonal Menu Adjustments: For restaurants, be ready to swap out or slightly modify dishes if an item becomes scarce or more expensive. Consider offering “holiday specials” that are easy to modify based on ingredient availability.

- Cross-Utilize Inventory: Both grocery stores and restaurants can benefit from cross-utilizing items. For example, if a protein is in short supply, offer a different cut or alternative that’s more readily available.

Minimize Waste with Smart Stocking Techniques

Managing inventory during peak seasons is also about reducing waste. Over-ordering can lead to excess stock, spoilage, and financial losses. To minimize waste, focus on purchasing perishable items in quantities that align closely with predicted demand.

Consider creative approaches for products with shorter shelf lives:

- Batch-Cooking for Restaurants: If you find yourself with an oversupply of an ingredient, use it in batch-cooked dishes or specials.

- Promotions in Grocery Stores: Use promotions to move slower-selling items, especially as you approach the end of the holiday season. In-store signage and discounts can drive quick sales of items with shorter remaining shelf lives.

Diversify Your Product Range with Specialty Items

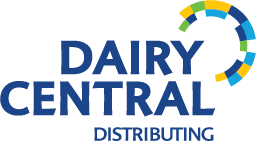

Holiday shopping often brings customers looking for unique, festive items, whether that’s a new flavour of specialty pasta, a holiday-themed condiment, or artisanal baking supplies. Stocking a limited range of holiday-themed specialty items not only helps attract more customers but also gives you options for creating unique offerings and bundles.

For grocery stores, offering specialty foods like imported chocolates or holiday-specific beverages can set you apart and increase seasonal sales. Restaurants can elevate their holiday menus with specialty condiments or rare spices.

Develop a Post-Holiday Inventory Strategy

As the holiday season winds down, you may find yourself with unsold holiday-themed items. Developing a post-holiday strategy for handling surplus stock can help minimize losses and make room for upcoming products.

- Hold a Post-Holiday Sale: Use discounts to clear out leftover holiday items quickly. This not only frees up space for new stock but also attracts cost-conscious customers looking for deals after the holiday rush.

- Repurpose Inventory for the Next Season: Items that aren’t strictly holiday-specific can often be repurposed for use in the new year. For example, certain baking ingredients or pantry staples can be marketed as “winter comfort” essentials.

Your Partner in Peak Season Success

Preparing for the holiday season and other peak periods doesn’t have to be overwhelming. With the right strategies for demand forecasting, flexible supplier relationships, and waste management, you can streamline your inventory management while maximizing sales and minimizing excess.

At CJR Wholesale & DairyCentral, we’re dedicated to supporting businesses through every season. By providing reliable, quality products and a responsive team, we ensure you have the inventory and flexibility you need to make the most of peak periods. Let us be your partner in holiday success, ensuring that your shelves and kitchens are stocked with exactly what you need, when you need it.

For more insights or to start planning for the upcoming new year, contact us today. Together, we’ll make this holiday season your most successful yet.